Recycled PE and Wood Composite WPC Decking Profile Extrusion Machine

The wood-plastic is a new kind of synthetic material which uses PVC,PP,PE resin or recycled plastic and plant fibre ( wood powder,chaff,straw etc.) as raw material and through the process of mixing,granulation,exrusion,calibrating,drawing off and cutting. This kind of wood-plastic materials are not only very similar with natural wood in appearance and feel,but also with the same characteristics as wood of excisable, planeable,sawable, unmatched grip,low bibulous rate, good moisture resistance, mothproof,mildew resistance,good resistance to acid and alkali,anti-corrosion, and it has the feature of fire resistance.The products are non-toxic,non-polluting,environment-friendly and save-energied, without formaldehyde, benzene and ammonia and other harmful substances.The wood-plastic products are widely used in outdoor floor,hydrophilic construction,balcony,landscape architecture,chairs and benches, fences, indoor doors and windows, furnitures, etc.

Material | Percentage |

Recycled PP/PE plastic material | 25-30% |

Wood powder made from wood/rice husk/rice straw/wheat straw/wheat husk | 65-70% |

Chemicals: PE wax, stearic acid, CaCo3, pigments, coupling agent | 5% |

Complete process for making WPC products from raw material to final products

1, plastic recycling: washing, crushing ,drying the PP/PE plastic wastage into flakes, the flakes shall be used for WPC production directly.

2, wheat straw powder making: crushing, milling and drying the wheat straw into 80-100 mesh powder

3, material mixing: weighting and mixing all material together according to our formula by hot mixing machine

4, WPC granulating: extrusion by parallel double screw extruder and do hot-pelletizing into WPC granules.

5, WPC extrusion: extrusion by conical double screw extruder and molding in required size and shape with water cooling calibrating, online fixed length cutting.

6, WPC surface design: embossing, brushing, or sanding on the surface to make different wooden grain feeling.

we are professional for the turnkey production line as below, we have all these machines in factory stock

Item | Machine | Capacity |

1 | Wood chipping machine: | 3 tons/hour |

2 | Wood crushing and milling machine: | 300kgs/h |

3 | Wood drying machine: | 300kgs/h |

4 | WPC Mixing machine: | 500kgs/h |

5 | SHMS75 WPC granulator machine: | 400kgs/h |

6 | SJMS65 WPC profile extrusion line: | 150kgs/h |

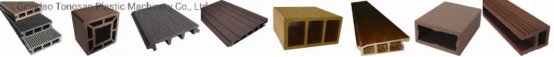

WPC profile molds: | ||

Co-extrusion system: | ||

Online embossing machine: | ||

7 | Off line sanding machine | |

8 | Off line brushing machine | |

9 | Off line double face embossing machine | |

10 | crusher |