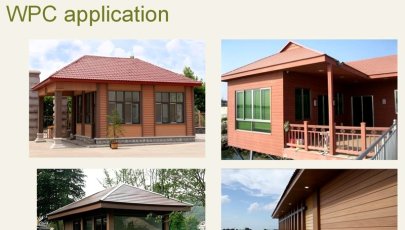

Tongsan Wood Plastic WPC machine is developed for using recycled PP/PE plastic mixing with agriculture wastage(such as wood sawdust, rice husk, rice straw, wheat straw) to make eco-friendly construction products, the max. wood percentage can be 70%. The Wood Plastic WPC machine is used for making WPC profiles by Wood and Plastic composition, such as WPC decking, WPC wall cladding, WPC fencing, WPC pergola, WPC post, etc...

We have the complete WPC PVC DOOR MAKING machines in our factory stock now. we have rich experience for providing turnkey project for WPC door making machine to dfifferent countries. if you are interested, we can also take you to visit our customer's factory to check the processing for making complete WPC doors from raw material to final product.

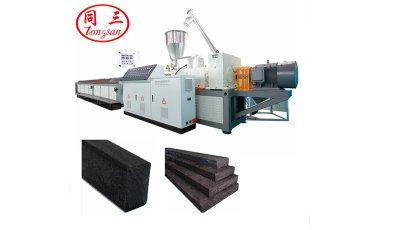

WPC board making machine SJMS80/156 Foam board production line

WPC decking profile making machine complete WPC production process We supply turnkey production line for WPC production with turnkey production plant.

PVC WPC door jamb profile machine is used for making Door jamb profile , the raw material is PVC and wood composition. the machine also can be used for making wall panel, ceiling panel, decoration profiles by changing mold.

This machine is used for making Plastic lumber by using recycled PE plastic scrap. the finished product can be widely used for making plastic furniture.

This production line is suitable for producing PP/PE WPC granule. The machine adopt high quality parallel double extruder, it can help the plastic completely be merged with wood and chemical additives and it has the advantages of high output and good plasticization. The PP/PE WPC granules are used to produce the WPC profiles, which ensures the products more durable.

The wood powder milling machine is composed of rough crushing device, storagebin, miller part, rotational flow tank, pulse dust collector, etc. This machine can continuously produce the wood powder in 40-100 mush. The wood powder can be used to make WPC products.

The newly designed wood powder dryer is improved with electromagnetic heating instead of the previous hot air heating. Besides, the machine adopts the screw pushing design and solve the material bridging problems, and also prevents the combustion and explosion might caused by excess temperature. The production efficiency has been improved by about 50%.