This high speed double wall corrugated pipe machine is suitable for 75-315mm diameter HDPE DWC pipe making. the machine has below advantages:

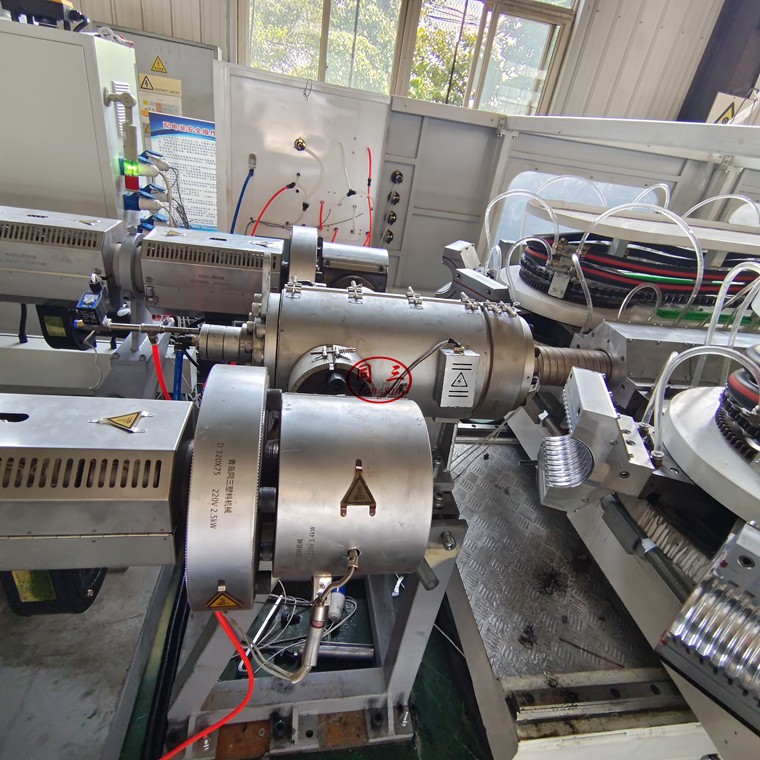

The optimized configuration of the extruder not only meets the production line's requirements for extrusion volume, but also minimizes the production line's consumption of electricity. The buffer design of the feeding section of the extruder greatly reduces the power of the main drive motor; the extrusion system with a large aspect ratio (36) meets the high-speed, efficient and high-quality extrusion of materials.

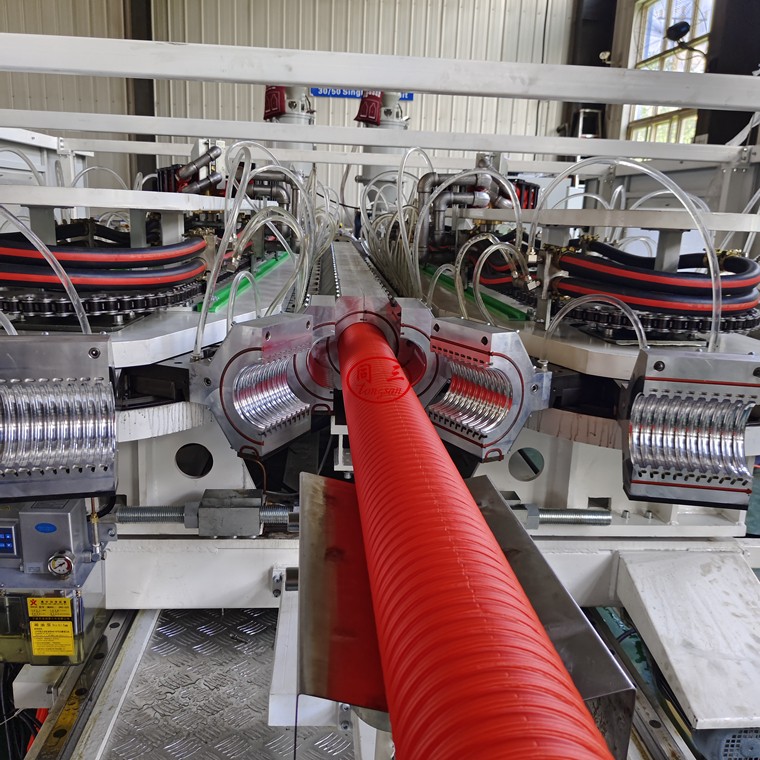

●The carefully developed mold operating channel has a more compact structure and smoother operation, making the molding equipment run more smoothly and the equipment have a longer service life.

●The surface of the mold running track is hardened using new technology. The hardened layer has high strength, does not fall off, and has a long service life.

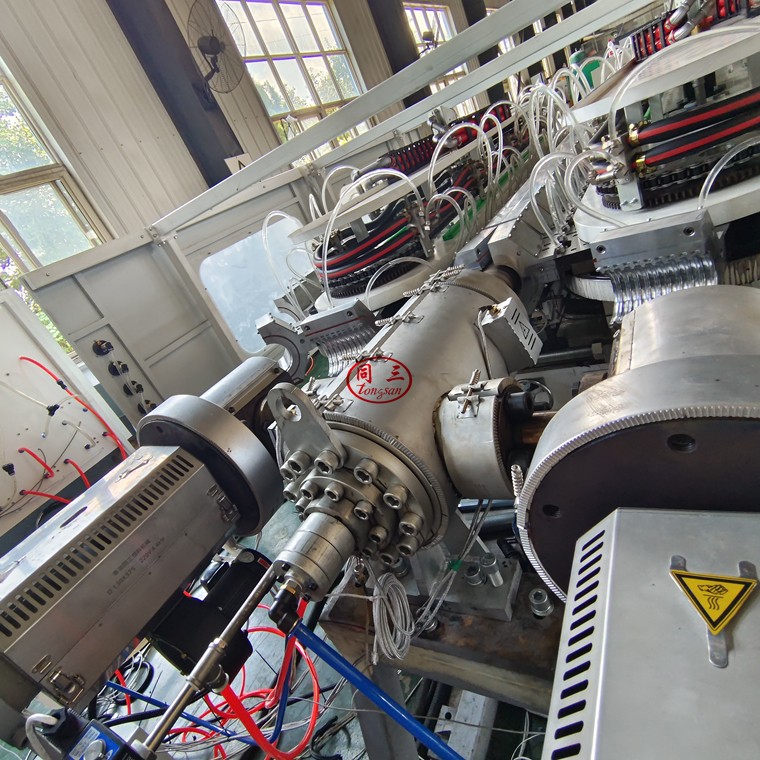

●The inner and outer side wall adjustment structure of the extrusion die has completely reformed the traditional side wall adjustment structure (first loosen the fastening screw, then adjust the wall thickness adjustment screw, tighten the fastening screw, extrude material to verify the adjustment effect, repeat Proceed until required); there is no need to loosen any fastening screws before adjusting directly. Easy to operate, avoid melt leakage and extend the use of the extrusion die.