HDPE PP Waste Plastic Wood Composite WPC Outdoor Beach Chair Bench Profile Making Machine

HDPE PP waste plastic wood composite WPC outdoor beach chair bench profile making machine

HGMSE series PP/PE WPC profile production line can continuously produce PP/PE WPC profile. The WPC profile adopts two -step production process. The granulating machine make WPC pellets using PP/PE recycled materials, wood powder and auxiliary agent. Then use this production line produce WPC profile.Customers can choose embossing machine for the production line to achieve 3D pattern performance.Customers can also make PE WPC single color or double color co-extrusion profile by adding extruders.The profile produced by this production line can be sanded and brushed by sanding and brushing machine.

The customer can use one extrusion line to produce different shape and size WPC profile by changing the mould. Such as WPC wall panel , WPC decking,WPC flooring,WPC fence, WPC post, WPC pallet, WPC chair,WPC house etc.

Plastic material | recycled PP/PE plastic |

Wood material | wood powder from rice husk/straw,wheat husk/straw,wood sawdust,wastage wood |

Percentage of plastic | 25-30% |

Percentage of wood powder | 50-70% |

Final product | WPC decking, WPC wall cladding, WPC pergola profile,WPC post, WPC fence profile, and other WPC construction profiles |

Production process | raw material--mixing--granulation--extrusion and molding--surface treatment |

The production process of WPC profile as follows:

(1) PP PE waste plastic crushing and cleaning machine.

To recycle waste PP/PE plastic to flakes.

Capacity:500kg/h

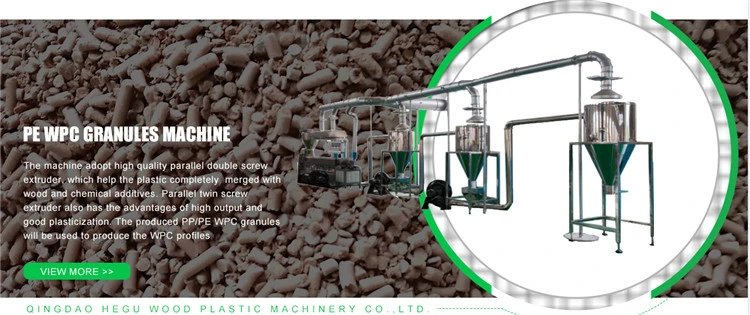

(2)PP./PE WPC granulating machine to make WPC pellets

After get ready wood powder and recycled PP/PE plastic, the first step is mixing them with chemicals, then use WPC granulation machine to make WPC granules

SHMS series granulating machine is used for making WPC pellets. The WPC pellets produced by WPC granulating machine can used for making WPC product using WPC machine.The granulating machine consists of parallel double-screw extruder,water cooling system, a granulator and air conveyor cooling system.The feeder and hopper are equipped with mixer to prevent the material blocked up.If customer do not have strict requirements about the appearance of pellets, the granulator can be removed.The pellets extrude by extruder directly, then go for crusher. Can improve the production capacity.

(3)WPC profile making machine to make different WPC profiles.

Material: recycled 30% PP/PE+70% wood powder+chemical additives.

Product: WPC decking, WPC wall cladding, WPC fence, WPC pergola..

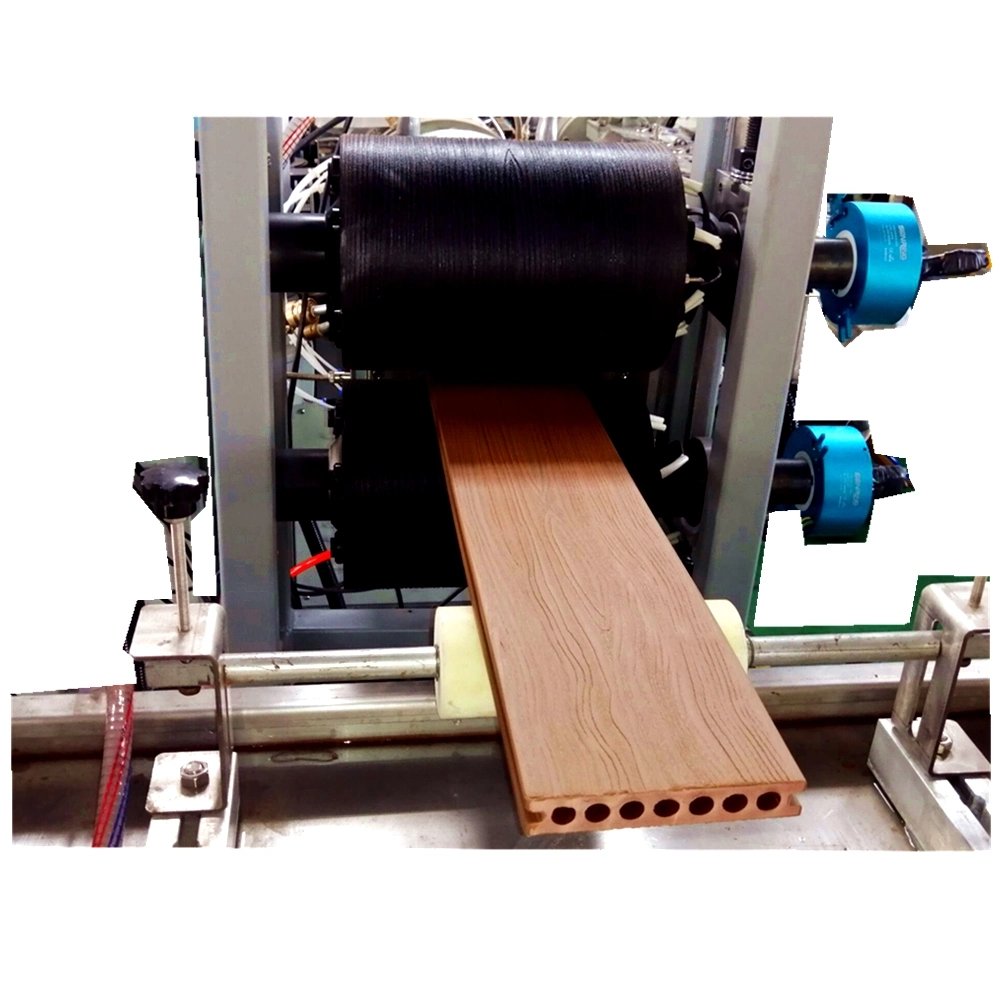

The WPC profile extrusion line can make WPC granules into WPC products by equipping required mold, we can equip co-extrusion system and online 3D embossing device for making WPC products in high quality with wooden grain, the line also equipped with online cutting device.

(4) WPC product wood surface making machine

Embossing machine, sanding machine, brushing machine, online embossing machine. these machines is for making WPC products with better wooden feeling design.

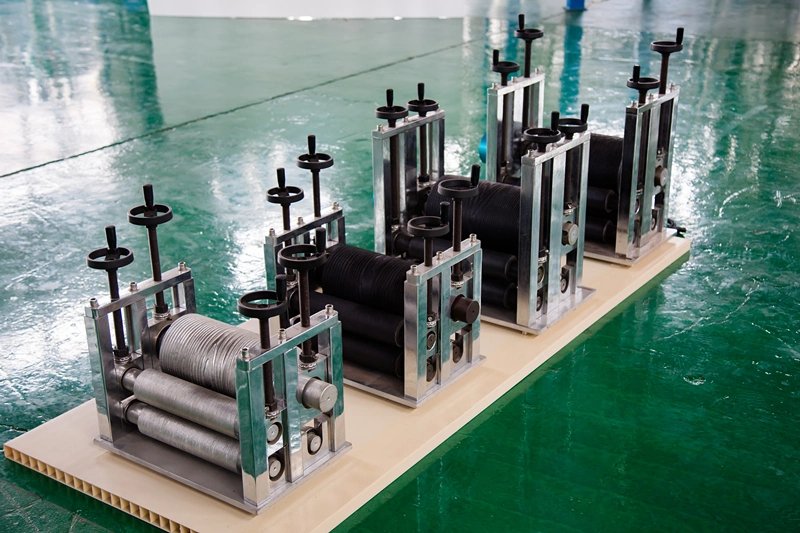

WPC embossing machine:

We have high quality embossing machine to make 3D pattern on the WPC profile.