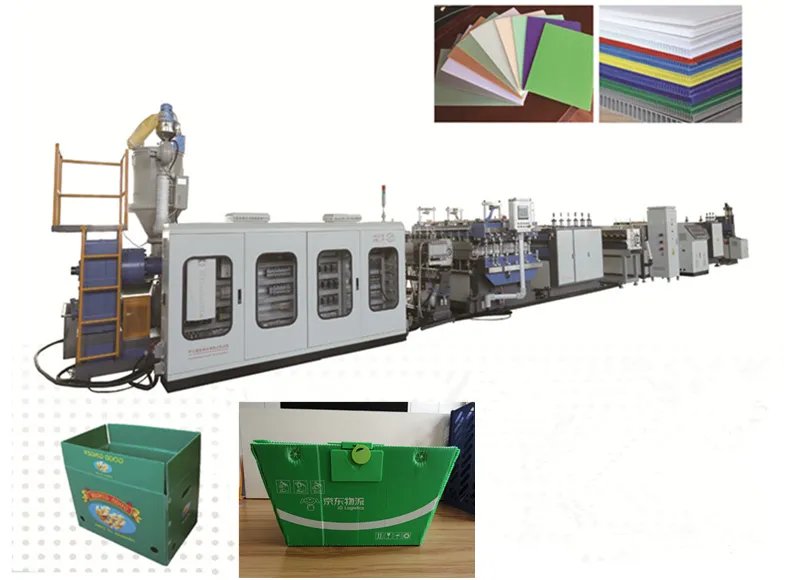

1.5mm 2mm 3mm 4mm 5mm PP Corrugated Sheet Machine / Plastic Hollow Sheet Extruder

PP PE Hollow Sheet Machine Plastic Corrugated Sheet Machine Plastic Packing Box Machine

Qingdao Tongsan Plastic Machinery co.,Ltd have been develop the PP hollow corrugated sheet making machine since 2015,now we have the machines for the PP hollow grid plate width from 1220mm to 2450mm and thickness from 1.5mm to 12mm.We have different model production line,such as the 1400 type PP hollow sheet extruder machine,1860 type PP corrugated sheet production line,2300 type PP hollow corrugated board making machine,2600 type plastic hollow grid panel making machine,and for each model,we have the co-extrusion type for customer choose.The co-extruder type can use 20%-60% fillermatch for reduce the cost,so our customer can produce the cost competitiveness sheet with goog quality.Our machine have the advantage of high output,easy operation,high precision,good products with smooth surface straight rib.

This production line realizes continuous production of PC/PE/PP hollow grid plate, which is applicable to construction decoration, advertisement collocation, and noise insulation of highway as well as packaging. PE/PP hollow grid plate is an ideal substitute for paper box in making packaging box. It is characterized by light weight, high intensity, dampproof, and anticorrosion. The width of the products is 1220-2100mm, and the thickness is 2mm-12mm.

Model | Sheet width | Sheet thickness | Extruder model | Motor powder |

TS-1400 | 1250mm | 2-6,8-12mm | 100/36 | 55-75kw |

TS-1860 | 1700mm | 2-6,8-12mm | 120/36 | 75-90kw |

TS-2300 | 2150mm | 2-6,8-12mm | 120/36 | 90-110kw |

TS-2600 | 2450mm | 2-6,8-12mm | 120/36 | 90-110kw |

TS-3000 | 2800mm | 2-6,8-12mm | 150/36 | 132kw |

TS-2600(F) | 2450mm | 2-6,8-12mm | 120/36&80/36 | 110+37kw |

Detailed images of machine

(1)Extruder for PP hollow sheet machine: high quality single screw extruder with high effective, special designed screw can help the PP material melted good in the extruder, and we can put recycled PP and 60% pp filler masterbatch for making low cost PP hollow sheet. the extruder is equipped with auto feeding system, auto temperature control system and low consumption driving system.

(2)Mould for pp hollow sheet machine:

Mould adopts high-quality alloy steel and throttling device to ensure even pressure of feed influent at the mould lips, and also differential action of up-down piece guarantee even thickness of the plate.

(3)Screen changer for pp hollow sheet machine :

Quick screen changer of hydraulic system ensures the short course of screen changing. Double-position combined with special sealing structure guarantee stable operation of screen changer.

(4)Vacuum calibrating table for PP hollow sheet machine:

Heating exchanging and cooling system of quick speed in calibrating system alternate effectively and ordinally with vacuum system, which ensures calibrating precision. Vacuum system composes two independent subsystems and each is equipped with several fixed circulating vacuum lines of three-point type. Meanwhile, each line carries vacuum regulating system and vacuum display system that realize even and stable vacuum degree of plate surface.