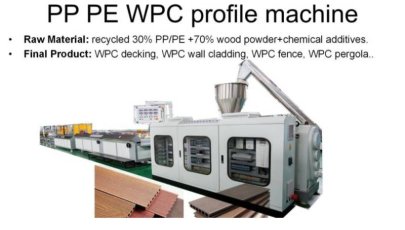

PVC / WPC profile making machine for window and door profile,ceiling,wall panel,skirting....

PVC / WPC profile extrusion line mainly use PVC or UPVC or PVC+wood powder to extruder profile such as building partition, cabinet door panels, window sill, skirting board, door edgeline, door jamb, window shutters, photo frame, mirror frame, furniture edge banding, door frame, door pocket, window pocket, column profile, stair handrail, floor board, decoration cladding panel, furniture, WPC pipes, etc.

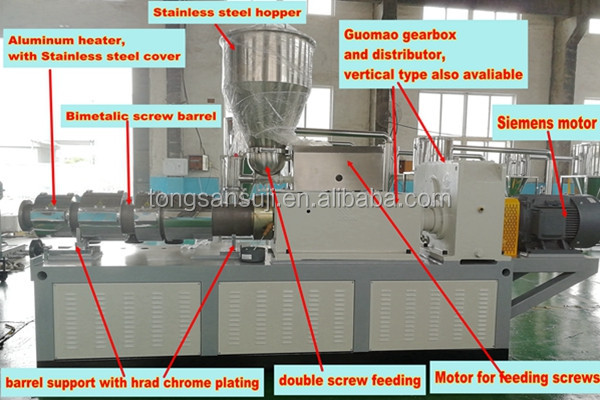

Detailed Images

Extruder for PVC window profiles making machine

Conical double screw extruder specially designed for making PVC window profiles door frame.

Model: SJMS65/132 model

Main power: 37KW

Capacity: 150-240 kg/h

Max. product width: 300-600mm

Die head and mold for the PVC window profiles making machine

the mould material is 3Cr17

calibrator length to be 300mm*3 piece or 300*4 piece or design according to product

and the water cooling tank will be 2000mm*2 pcs or 3000mm*2 pcs or design according to product

calibrating machine PVC window profiles making machine

Length of table: 6meter or 8meter customized

width of table: 1100mm, valiable inner width is 600mm

material of table: stainless steel

cooling method: water cooling and vacuum cooling.

vacuum pump: 7.5kw*1 sets,+5.5kw*2 sets

water pump: 2.2kw*1 set

haul off machine for PVC window profiles making machine

Haul off type: double caterpillar

length of haul off: 2.4 meter

control of haul off: frequency control

motor : 1.5 kw

gearbox: double gearbox

Cutting machine for PVC window profiles making machine

cutting method: automatic cutting

cutting control: PID control

Length: fix length cutting

Electric control cabinet

ABB inverter

Siemens contractor

Omron temperature

Siemens PLC is optional