PP hollow sheet extrusion machine making corrugated flute sheet

PP hollow sheet is mainly used in various fields of machinery, electron, appliance, food, advertising, interior decoration material, glass agricultural product etc packing and transporting.

The sheet has the advantages of non-toxic, no smell, pollution-free, anti-moisture, corrosion resistance, light quality, tough-resistance, thermal shock proof, economy and durability, rich colors etc. It processes other advantages, like folding resistance, stretching resistance, strong bearing force.

Main Features

1) The plastic hollow sheet is eco-friendly new material in the market.

2) Adopting advanced world famous brand components in pneumatic parts ,electric parts and operation parts.

3) The plastic hollow sheet has wide market prospect.

4) Running in a high automatization and intellectualization,no pollution .

5) Excellent Configuration, Stable Operation, High Production Efficiency.

Detailed Images

Loader with dryer system

Stainless steel hopper

Hot air dryer

Agitator

Single Screw Extruder

The specially designed screw and the advanced controlling system ensure excellent plasticization,high output and stable extruding.

We also have the co-extrusion type to use the recycled plastic to reduce the cost with high quality products.

Hydraulic Screen Changer without shutdown

Heating type heating rods

Working pressure 10-20mpa

Quick screen changer of hydraulic system ensure the continuously working of screen changing.Double position combined with special

sealing structure guarantee stable operation of screen changer.

Mold

Mold material Alloy steel forging.

Heating type Heating rods.

Mould adopts high-quality alloy steel and throttling device to ensure even pressure of feed influent at the mould lips,and also differential action of up-down piece guarantee even thickness of the plate.

Flowmeter

Air pressure control Barometric flow controller

Vacuum forming machine

Mold material Alloy steel casting

Cooling medium Water

Calibrating type Minus pressure molding

Vacuum pump power 11kw

Vacuum tank type Slot type

Air fan power 1.5kw

Mold elevation type Pneumatic

Back-and–forth movable distance 100cm

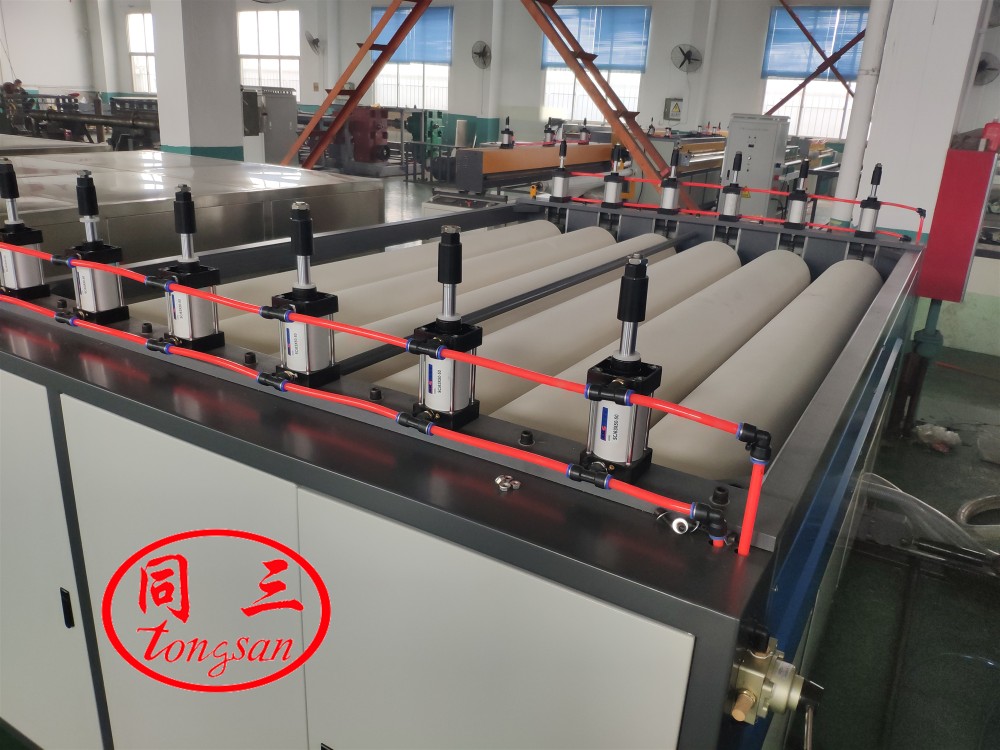

Six –roller pull off machine

Rubber material Silicone rubber

Pull off line speed 1-8 m/minute

Clamp type Pneumatic

Motor type 7.5kw

Heating Oven

Model 2300

Heating type Heating rods

Heating power 30kw*2 sets

Elevation type Pneumatic

Cover insulation type Rock wool

Three–roller pull off machine

Rubber material Silicone rubber

Pull off line speed 1-8 m/minute

Clamp type Pneumatic

Motor power 4kw

Double-side corona

In order to improve the surface tension of the hollow sheet surface, and thereby improve the printing ink fastness, the hollow corrugated sheet surface will under corona treatment, so that the surface produces micro-concave dense holes, plastic surface roughening, increase the surface activity.

Transverse Cross cutting unit

Cutting thickness : 8-12mm

Clamping type :PPneumatic

Metering type:Rotary encoder Autonics brand

Power of motor : 2.2kw

Cutting type: Automatic

Back-and -forth moving type : Pneumatic

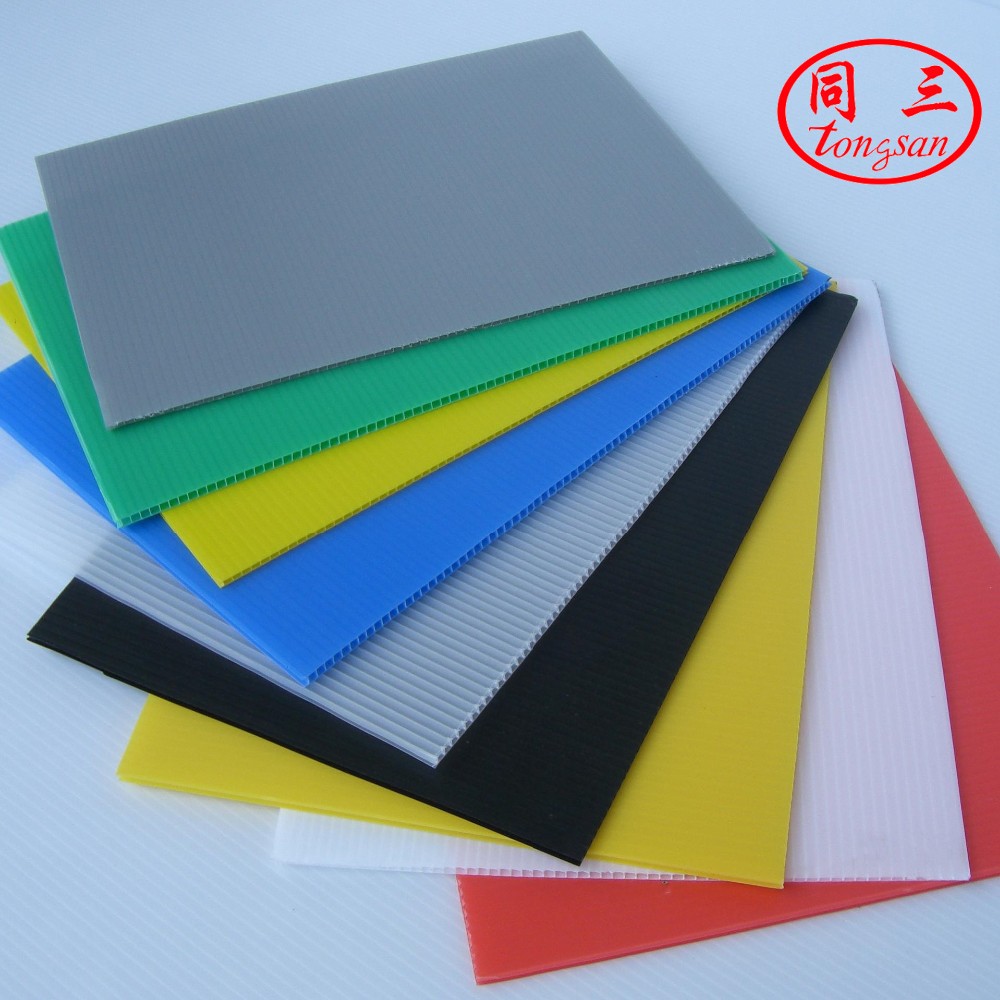

Final Product

The hollow sheet is widely used in machinery,electron,appliance,food,advertising,interior decoration material,glass,agricultural product etc packing and transporting.

With the developing of e-commerce,the container is used largely more and more ,the logistics industry proposes high demand for the packing materials which are easier to use and transport,require simply technology and can be finished in short time.

Related Products

Automatic Die-cutting Machine

For cutting the Pp sheet into required shape for folding box.

We can provide the automatic printing and die cutting machine with the extrusion line.

Printing Machine

For printing logo and designs on the Packing box, there is different printing machine,

such as single color printer, double color printer, four color printer.

Bookbinding Machine

For folding the Pp hollow sheet into required box shape, welding machine and bookbinding

machine both can work for it