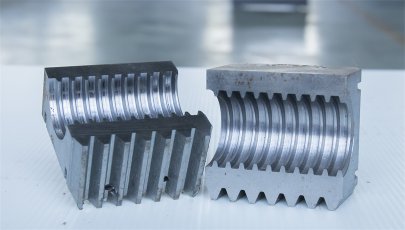

GSDBGZ series high speed single wall corrugated pipe extrusion line can produce PE, PP, EVA, PVC, PA corrugated pipes. By technical upgrade, replaced the traditional chain type forming machine, the pipe surface and precision is improved significantly. This high speed corrugated pipe production line adopts gear transmission, mould use 40Cr material, Nitriding process. Mould is running in the track, with automatic oil lubrication system and closed forced water cooling system, it can achieve high speed production. By equipped with vacuum pump and vacuum type mould, it can produce different use corrugated pipe with joint (wash basin drain pipe, air conditioner pipe, hookah pipe etc) In one mould, it can produce 2 size pipe, the two pipe outside diameter A+B should less than 45mm. In the production, by adjust the molding machine up and down to produce corrugated pipe of different diameters.

GSDBGZ series high speed single wall corrugated pipe extrusion line can produce PE, PP, EVA, PVC, PA corrugated pipes. By technical upgrade, replaced the traditional chain type forming machine, the pipe surface and precision is improved significantly. This high speed corrugated pipe production line adopts gear transmission, mould use 40Cr material, Nitriding process. Mould is running in the track, with automatic oil lubrication system and closed forced water cooling system, it can achieve high speed production. By equipped with vacuum pump and vacuum type mould, it can produce different use corrugated pipe with joint (wash basin drain pipe, air conditioner pipe, hookah pipe etc) In one mould, it can produce 2 size pipe, the two pipe outside diameter A+B should less than 45mm. In the production, by adjust the molding machine up and down to produce corrugated pipe of different diameters.

GSDBGZ series high speed single wall corrugated pipe extrusion line can produce PE, PP, EVA, PVC, PA corrugated pipes. By technical upgrade, replaced the traditional chain type forming machine, the pipe surface and precision is improved significantly. This high speed corrugated pipe production line adopts gear transmission, mould use 40Cr material, Nitriding process. Mould is running in the track, with automatic oil lubrication system and closed forced water cooling system, it can achieve high speed production. By equipped with vacuum pump and vacuum type mould, it can produce different use corrugated pipe with joint (wash basin drain pipe, air conditioner pipe, hookah pipe etc) In one mould, it can produce 2 size pipe, the two pipe outside diameter A+B should less than 45mm. In the production, by adjust the molding machine up and down to produce corrugated pipe of different diameters.

GSDBGZ series high speed single wall corrugated pipe extrusion line can produce PE, PP, EVA, PVC, PA corrugated pipes. By technical upgrade, replaced the traditional chain type forming machine, the pipe surface and precision is improved significantly. This high speed corrugated pipe production line adopts gear transmission, mould use 40Cr material, Nitriding process. Mould is running in the track, with automatic oil lubrication system and closed forced water cooling system, it can achieve high speed production. By equipped with vacuum pump and vacuum type mould, it can produce different use corrugated pipe with joint (wash basin drain pipe, air conditioner pipe, hookah pipe etc) In one mould, it can produce 2 size pipe, the two pipe outside diameter A+B should less than 45mm. In the production, by adjust the molding machine up and down to produce corrugated pipe of different diameters.

GSDBGZ series high speed single wall corrugated pipe extrusion line can produce PE, PP, EVA, PVC, PA corrugated pipes. By technical upgrade, replaced the traditional chain type forming machine, the pipe surface and precision is improved significantly. This high speed corrugated pipe production line adopts gear transmission, mould use 40Cr material, Nitriding process. Mould is running in the track, with automatic oil lubrication system and closed forced water cooling system, it can achieve high speed production. By equipped with vacuum pump and vacuum type mould, it can produce different use corrugated pipe with joint (wash basin drain pipe, air conditioner pipe, hookah pipe etc) In one mould, it can produce 2 size pipe, the two pipe outside diameter A+B should less than 45mm. In the production, by adjust the molding machine up and down to produce corrugated pipe of different diameters.

GSDBGZ series high speed single wall corrugated pipe extrusion line can produce PE, PP, EVA, PVC, PA corrugated pipes. By technical upgrade, replaced the traditional chain type forming machine, the pipe surface and precision is improved significantly. This high speed corrugated pipe production line adopts gear transmission, mould use 40Cr material, Nitriding process. Mould is running in the track, with automatic oil lubrication system and closed forced water cooling system, it can achieve high speed production. By equipped with vacuum pump and vacuum type mould, it can produce different use corrugated pipe with joint (wash basin drain pipe, air conditioner pipe, hookah pipe etc) In one mould, it can produce 2 size pipe, the two pipe outside diameter A+B should less than 45mm. In the production, by adjust the molding machine up and down to produce corrugated pipe of different diameters.

GSDBGZ series high speed single wall corrugated pipe extrusion line can produce PE, PP, EVA, PVC, PA corrugated pipes. By technical upgrade, replaced the traditional chain type forming machine, the pipe surface and precision is improved significantly. This high speed corrugated pipe production line adopts gear transmission, mould use 40Cr material, Nitriding process. Mould is running in the track, with automatic oil lubrication system and closed forced water cooling system, it can achieve high speed production. By equipped with vacuum pump and vacuum type mould, it can produce different use corrugated pipe with joint (wash basin drain pipe, air conditioner pipe, hookah pipe etc) In one mould, it can produce 2 size pipe, the two pipe outside diameter A+B should less than 45mm. In the production, by adjust the molding machine up and down to produce corrugated pipe of different diameters.

Corrugated pipe mold making: we have our own workshop and CNC machines to make corrugated pipe molds by ourself, we also has design team for design the corrugated pipe molds according to customer's requirements.