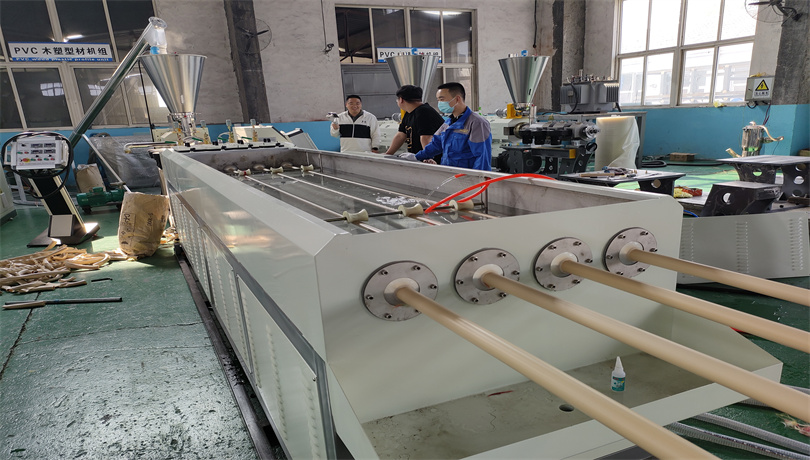

PVC pipe extrusion machine making water waste PVC drain pipe

we have different models of PVC pipe making machine for making different PVC pipe diameter, below is our PVC pipe plant cost for your reference:

High Output Small Diameter PVC Pipe Production Machine

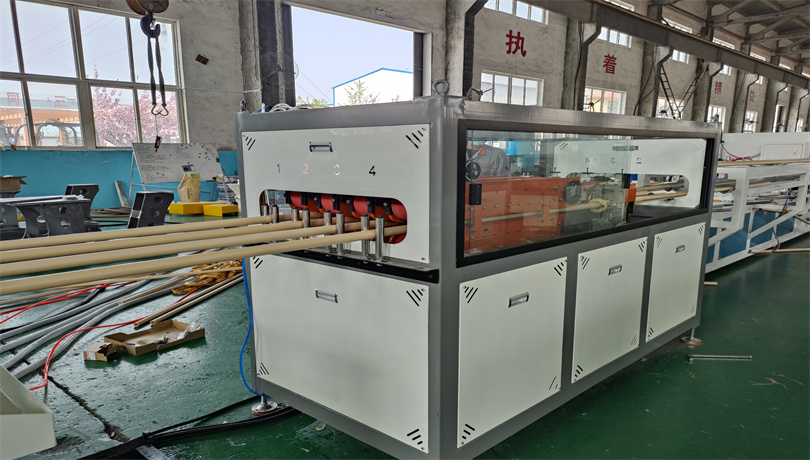

4 cavity output PVC pipe extrusion machine can produce 16-32mm PVC Pipe for electric conduit, water supply and drainage PVC UPVC pipe.The advantage is it can provide 4 piece PVC pipes at the same time, improved prodcution efficiency.

4 cavity PVC Pipe Extrusion Machine Production Process:

Raw Material Mixing-Feeder-Extruder- Die Head and Mould- Vacuum Calibration & Water Cooling Tank-Double Haul Off and Cutting Machine- Stacker

4 Cavity PVC Electric Pipe Production Line Model:

Model | Pipe diameter (mm) | Extruder type | Production speed(m/min) | Capacity (kg/h) | Installed power (kw) |

TS-40 | 16-40 | SJSZ-65/132 | 1-10 | 150-200 | 60 |

PVC Pipe Extrusion Line Features:

1. Powder feeder: It is made of high quality stainless steel. It has the characteristics of high pressure and corrosion resistance. It can transport PVC powder well.

2. Conical twin screw extruder: It is equipped with a mandatory quantitative feeding system, automatic temperature control system, vacuum exhaust system and automatic speed control system to ensure accurate control of the material temperature and plasticization of the stability.

3. PVC pipe mold: Mold material is 45 # quenched and tempered steel by forging processing and surface polishing. Due to the low melt pressure, it can keep the low melt temperature in high extrusion.

4. Vacuum calibration tank: Due to the high hardness and high quality stainless steel plate manufacturing, the tank is resistant to high pressure and corrosion resistance.

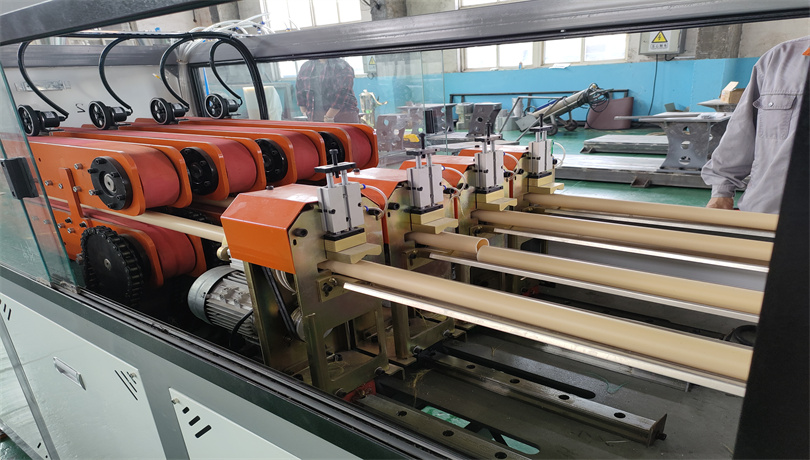

5. Hauling machine: It adopts frequency control mode. The traction frame using the chain of sub-moving to ensure that the traction speed of the same, flexible pneumatic compression, bearing with Block-aligning structure, can effectively reduce the installation error. It uses V-type high friction coefficient rubber block.

6. Cutting machine: It uses the form of lift knife cutting. This cutting method is simple and effective. It has the characteristics of fast speed, low failure rate, and significant cost savings.

7. Stacker: The pipe can be placed on the top of its.